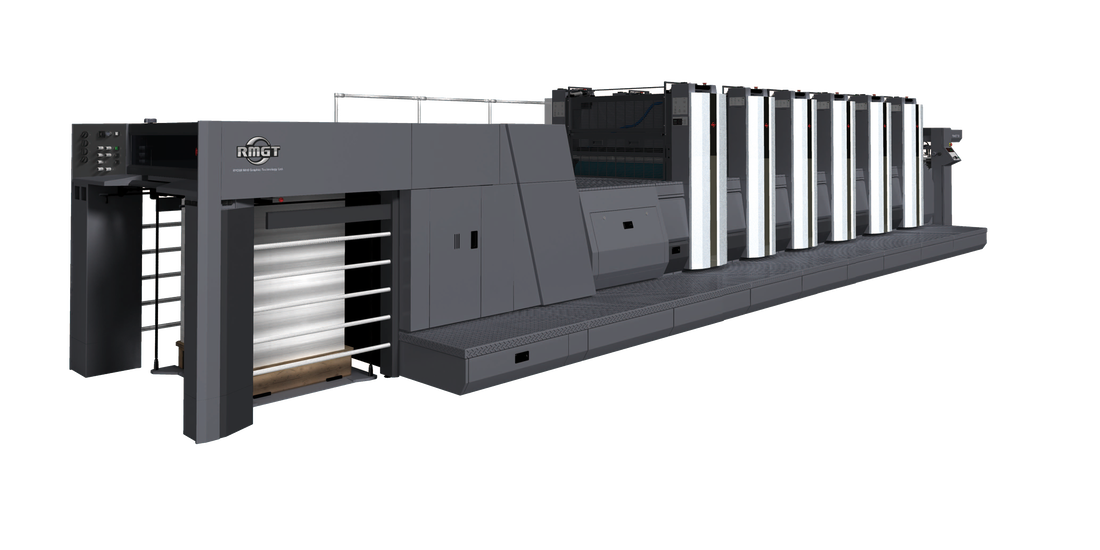

Inline Roll Sheeter Feeds JD Graphic’s RMGT 8-color 920 Perfector reducing paper costs by 35%6/11/2024

3rd-generation, Chicago-area commercial print firm rolls through some 125 tons of paper weekly, printing direct mail and books on its four-year-old, sheetfed-offset press.

CLEVELAND, OH – Feb 29, 2024 – RMGT, manufacturer of the leading 8-up sheetfed offset press in North America, announces that JD Graphic, a third-generation, Chicago based commercial printing company, created a new dynamic when they added a roll sheeter to their full-size 8-color RMGT 920 perfecting press. Installed by Graphco, the exclusive RMGT distributor in the midwestern United States, and operational since August 2020, the configuration is the second of its kind in North America featuring a roll sheeter from Quantum Design that converts rolls to sheets inline on the press. The four-over-four perfector also is equipped with LED-UV technology for instant curing. With three-and-a-half years of history to date, JD Graphic’s team reports doing double the makereadies compared to the 2007 vintage sheetfed device that the newer model replaced. Getting up to color faster translates to less paper waste. “We are saving 35% in paper costs,” explains Nick DeBlasio, Vice President, JD Graphic Co. “When spending between $3 million and $4 million annually on paper purchases, that savings is huge – amounting to somewhere between $1 million and $1.4 million per year!” “We store four million pounds of paper on the floor at any given time,” explains DeBlasio, whose grandfather (James, Sr.) started the company 61 years ago on Chicago’s historic Printer’s Row. In the early 1970s, he moved his then web-offset presses to the northwest Illinois suburb of Elk Grove Village. Today, JD Graphic’s 49 full-time employees work three full shifts to keep the press busy with work. “Last year, we mailed more than 125 million pieces,” DeBlasio reports proudly, adding that they go through approximately 250,000 pounds of paper per week. That high volume represents literally tons of direct-mail printing. But self-mailers and postcards are not all that JD Graphic prints. Thanks to the newer press, the firm’s business has been propelled into competing for more book and booklet printing. “Producing book work is much more efficient now,” DeBlasio notes, “because we can run 16-page signatures.” Full size press with compact footprint

As Derek Gordon, Midwest Regional Manager at Graphco, points out: “Keep in mind that the RMGT 9 Series is a full-size [38”], eight-up printing press that delivers 8½ x11” signatures. Then, there’s the long perfector’s ability to print double-sided to consider. Running 13,000 full-color printed sheets (25x36”) per hour in only one pass through the press can be a big competitive advantage.”

The RMGT 8-UP+ format has an industry leading smaller footprint. This played a role in the choice of JD Graphics, which operates two production facilities totaling 55,000 square feet. “We have space constraints,” acknowledges DeBlasio, who hinted that another building may be added later this year. Post-press finishing work, including folding, gluing and binding, is performed at a nearby location. JD Graphic’s book volumes have grown to the point of adding a Horizon 270 perfect binder ten months ago. “We put 400,000 books on that machine last year,” DeBlasio says, adding that the post-press department soon may be ready for a multi-clamp version. Nick DeBlasio concludes that he and his father could not be more pleased with the RMGT 9 Series performance. “We are producing at about half the cost, and our [profit] margins are still good,” he says. “This press has exceeded our expectations by far. All the great things that we heard about it prior to 2020 have been validated.”

SOLON, OH – May 28, 2024 – RMGT, manufacturer of the leading 8-UP sheetfed offset press in North America, announces that Graphco has installed an 8-UP+ five-color RMGT 970 press at 3 Dimension Graphics, Inc. in Doral, FL. Situated 14 miles northwest of Miami, the commercial print firm employs 34 full-time employees who produce flyers and folding carton work as well as brochures and magazines for travel/tourism customers and direct mail for Florida’s convention business. The RMGT 970 press features a coater as well as LED-UV technology for instant ink curing.

Running at 16,000 sheets per hour on the one-year-old machine, print quantities have ranged from as small as 500 pieces up to 60,000 or more. On the lower end of the volume spectrum, the RMGT 970 8-UP+ format allows the company to compete with digital devices, according to Jaime Cadena, Owner and President of 3 Dimension Graphics, Inc. Cadena says he appreciates the RMGT’s versatility: “From 60-lb. text weight [paper] to 24-pt. board, synthetic paper to plastic; there’s no throughput limit. It’s very versatile and reliable.” His 24-year-old firm occupies three buildings spanning nearly 40,000 square feet. The full-size 8-UP+ RMGT 970 sits in the same spot as the 28-inch offset press it replaced. “We don’t have a lot of space, and this machine is so compact that it fit where our L528C was located, but we are now producing double the sheet size,” Cadena points out. He normally runs three full shifts with a head pressman and helper – except when it comes to the new, automated full size 38-inch press, which is highly efficient and only requires one operator. “Our cost savings over 3 shifts is incredible.” “Productivity is up, and labor cost is down,” reports Chris Manley, President of Graphco. “That formula is a win-win for any provider of printing services. On a national average, a press helper adds over $53,000 in overhead cost per shift, so our 3-shift customers enjoy a $160,000 in annual labor savings versus a 40” press. We talk about The Unfair Advantage a lot at Graphco, and this savings alone pays for WAY more than half of the 9 Series press’s monthly payment. Add in a lower capex and much lower operating costs on a press that prints beautifully and runs full blast, and you can see why we are landing these machines in 28” and 40” shops all over the country.” Consistent color & increased capacity

Cadena notes that, despite its high-end automation, the new press is intuitive and easy for semi-skilled operators to run. “There’s a little bit of an adjustment, like when you buy a new cell phone,” he says. With 12 months of press history now in the books, he confirms that plate changes are quick, with complete makereadies averaging 15-20 minutes.

Overall, “our efficiency and savings have improved by 25% to 30%,” he reports. “The RMGT is my dream machine . . . better than any other machine in the market, and buying it is one of the best decisions I’ve ever made!” Such strong feelings stem from the consistently high level of performance he has witnessed. Cadena estimates that quality levels have jumped by a factor of 20%. “Our customers, especially those in the resort and packaging businesses, can be very demanding,” he notes. “We’re proud to receive many compliments about how amazing everything is looking.” Even leaders at other printing firms, for which 3 Dimension Graphics, Inc. produces trade jobs, have taken notice in the past year. “We get up to color fast,” Cadena says. Not only do colors “pop” vibrantly, but the new press’ consistent output is what really has captured his attention. “Listen, every manufacturer can offer high quality [output] today, but consistency is the key,” he explains. “The registration and sharpness of the dot from this RMGT 970 press is outstanding. My operators can pick a sheet, any sheet, and the color is the same throughout the run.”

Also, the ability to “go from little to big” complements 3 Dimension Graphics, Inc.’s existing 40-inch sheetfed press on the floor, Cadena believes. “On the RMGT, we can easily switch from 11x17” format to full, 25x38” sheets,” he notes. In addition to flexibility, an added advantage is that consumables cost less for the smaller format press.

Cadena considered trading in his 40-inch press, along with the 28-inch model, for a new, faster, automated 40-incher from one of the other major Japanese suppliers. Losing capacity was a big issue in the other supplier’s proposal. “By going with RMGT and Graphco, I got more power with less investment,” he notes. In fact, capacity has doubled at 3 Dimension Graphics, Inc., which now can run 16-UP with both presses, versus only 8-UP with the alternative proposal. 3 Dimension Graphics, Inc. also has a complete finishing department, including a die cutter and inline gluer, for the packaging boxes it produces for cosmetic, food and vitamin products. The 970’s .024” board stock specification meets 95% of all folding carton requirements, and the great thing is that in 2-3 minutes time this highly versatile press is producing 80 lbs. text weight jobs as well. American success story Originally from the Dominican Republic, Cadena received a vocational scholarship to Universidad de Puerto Rico, earning a Graphic Arts associate degree in 1990. In 1994, he began a six-year stint at Colonial Press International (Miami), one of Florida’s largest printers, where he progressed to General Manager of its sprawling, 300,000-square-foot sheetfed and web-offset printing facility. As General Manager, Jaime directed all facets of this $60 million dollar operation, so his background includes management of pre-press, web and sheetfed pressrooms, and full service bindery operations. Taking all the valuable experience he gained at Colonial, Cadena ventured out on his own in mid-2000 to start up 3 Dimension Graphics, Inc. For the past 23 years, he has worn many hats. “I do sales, production, estimating, you name it!” he says with a friendly smile – and he does it all for his wife, Jasmine, and their three boys, who joined him last year for a memorable trip to Japan to visit the RMGT factory. Manley concludes with this observation: “All of 3 Dimension Graphics’ departments – prepress, pressroom and post press – are so well organized. Graphco has sold over 50 of these machines in the United States, and the cohesion among staff is phenomenal. During the week that Jaime, his family, and I enjoyed in Japan, the deep understanding I gained of how a gentleman who came to the USA from another country can not only succeed, but thrive here in the USA was refreshing. We visited the RMGT factory, the Peace Memorial in Hiroshima, plus Kyoto and Tokyo during the trip, and Jaime’s young sons kept up with our tour 100%. I think 3 Dimension Graphics, Inc. truly embodies that same family achievement atmosphere, and Graphco is proud to play a role in making 3DG a great company.” A beneficiary of the nationwide home-schooling trend, this religious-educational publisher plows through a tractor-trailer load of paper (monthly) on new printing press.

SOLON, OH – April 24, 2024 – Graphco, the Exclusive Distributor for RMGT’s most popular 970, 920 and 790 offset presses, throughout the Midwest and Southeast, has installed another 8-UP+ RMGT 970PF perfector at Rod & Staff Publishers. Situated in the mountainous, Appalachia region of eastern Kentucky, the Christian publishing company supplies Bible-based, educational textbooks and workbooks – for first through tenth-grade students and their teachers. Rod & Staff’s customers include Mennonite and Amish parochial schools throughout America, and internationally, as well as to parents who home-school their children.

Installed in early 2021, Rod & Staff’s press became the very first 970PF (perfector press) installed in North America. The highly automated RMGT printing press, which replaced a 29-year-old, 40-inch press, perfects at 15,000 SPH and changes all plates in under 4 minutes. “We use a tractor-trailer load or more of paper per month,” notes Luke Miller, Production Manager of the 15,000-square-foot manufacturing facility that has been operating in Crockett, KY, since 1960. Two-over-two-color textbooks account for nearly half of the nonprofit organization’s $4.4 million in annual sales. “Using black ink, with correct answers highlighted in a Pantone, spot color, works best for the teaching manuals,” Miller says.

This faith-based publisher offers more than 400 educational titles via a printed catalog, which it updates annually and mails to some 27,000 recipients in 40 countries. Running a single shift, five days per week, Rod & Staff’s 35 full-time employees also reproduce curriculum aids and materials for Bible studies. (Periodicals and Spanish-language versions are produced at a smaller plant in Wisconsin.)

“Most of our private-school customers are very small, with only 30 to 40 students total,” reports Miller. “And now, approximately three of every four books we print go to the home-schooling market, which has become very popular. In our busy season, we may receive as many as 200 calls per day.” The number of U.S. home-schooled students tripled during the COVID-19 pandemic and has sustained impressive growth since – rising by an average of 51% in several states, according to the Washington Post – from rural areas to large metropolitan cities. (Parts of New York City have seen a 300% expansion!) Nationally, between 2 million and 2.5 million students presently are being schooled at home, according to Post analyses conducted in late 2023. That number far outpaces the rate at private (+7%) and public (-4%) schools. Kentucky has 19 school districts where there was at least one home-schooled child for every 10 enrolled in the public school system during the 2021-22 school year. There were 48 such districts in Arkansas and 46 in California, according to The Post. In Knox County, KY, public school enrollment has declined 16% during the last six years while its number of home-schooled students grew 80%. Waste not, want not

First printings for new publications typically vary somewhere between 1,500 and 2,500 copies. “When we reprint books, we usually run a two-year supply,” Miller says, adding that with the new, more efficient technology from RMGT, time spent on press for rerun makereadies has been cut by nearly one-third.

“Much of our work is perfecting – printing the inside pages of our textbooks on offset paper,” notes Press Foreman Sidney Sensenig. “We also like this press for our 23x29-inch, 12-pt. C1S [coated on one side] greeting cards; our RMGT produces these cards at a much higher quality than we produced in the past.” The crew prints an increasing amount of straight run, four-color work for book covers that are then UV coated near-line on the TecLighting coater Rod & Staff also sourced from Graphco. “Due to our relatively low volume of UV coated work, adding the in-line coater didn't make economic sense, but the high shine we get from the near-line coating approach works well and looks great.” Machine dimensions played a large role in Rod & Staff’s purchasing decision. “The standard, 40-inch size press was larger than we needed for most of our work,” Sensenig explains. “Like most book printers, we generally use 23x35-inch sheets, so the 970’s size is a perfect fit for our operation: Big enough to run even our 25x38-inch work, but also efficient for the many jobs we do using 31.5x22.5-inch sheets – to create 16-page signatures for school textbooks.” At first, however, Rod & Staff did not think it could use this press to print 32-page signatures for 6x9-inch, full-bleed textbooks. “Sidney and his team were able to make this work by reducing the folding margins from a normal 26x38-inch sheet to fit a 25.5x38-inch sheet,” explains Gary Greis, Regional Sales Manager for Graphco. “They are easily able to print to the edge of the blanket, and with RMGT’s powerful inker it's working fine.” The customer even runs quite a bit of lightweight 40-pound paper stock on the RMGT press with great success,” Greis adds: “Many jobs run the full 25x38-inch size on a 40-pound commodity sheet, and the press feeds and prints great! As the former President of Hennegan, a large printing company with 5 full size presses, I love to walk through that back door to Rod & Staff and see Luke running his RMGT full blast.” The press crew reports a very small amount of waste sheets, according to Sensenig, “often less than 50 sheets upon startup.” On reprint jobs, Miller has calculated 21% less spoilage. “Manually adjusting ink keys is basically unheard of on this press,” Sensenig continues. “Just pull a sheet and place it under the scanner. After scanning, touch the feedback button and, immediately, precise ink key adjustments are made to the whole press!” Ink control is another big plus, per Sensenig: “The ink settings are downloaded from prepress.” Chill Performance

Chilled ink rollers have been well worth the cost, too, he continues, “even though we use conventional ink. With this cooling system, there is very little adjustment to the dampening. On cool mornings, the temperature controller even heats the rollers, keeping them at a steady 80 degrees [Fahrenheit] all day long for optimum ink viscosity,” says Sensenig.

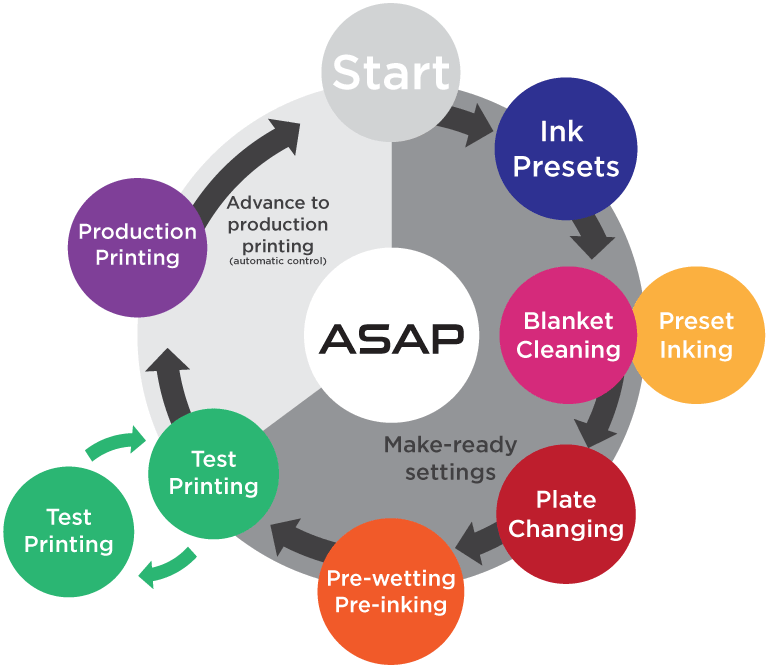

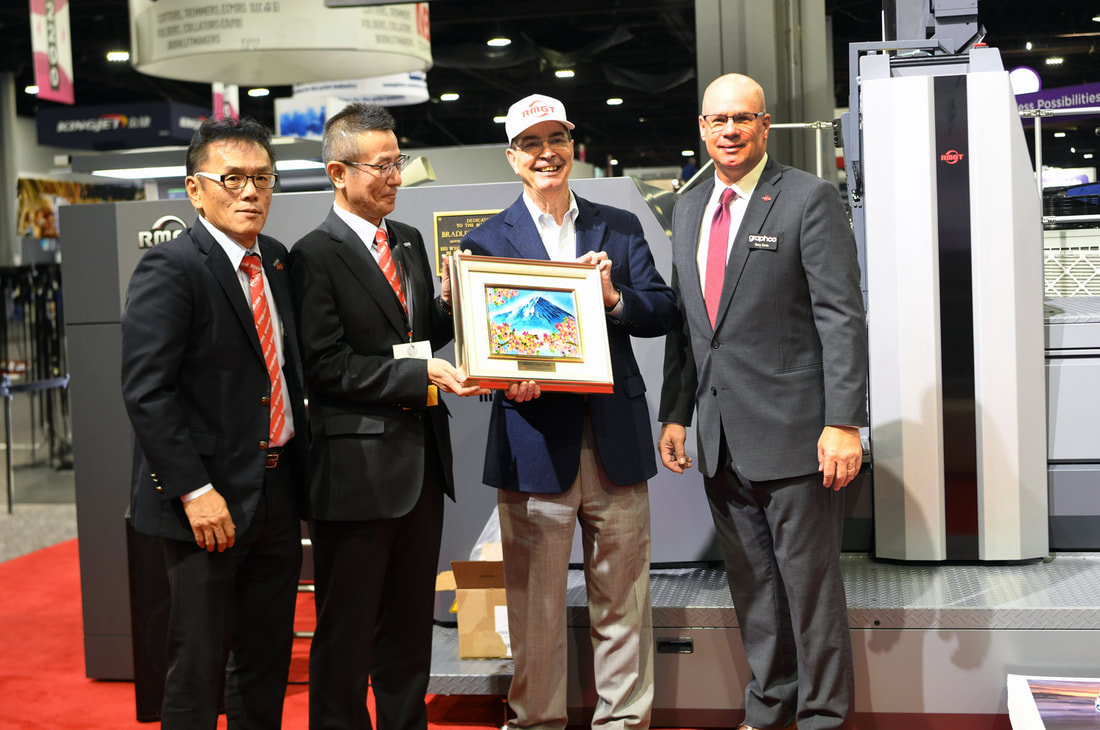

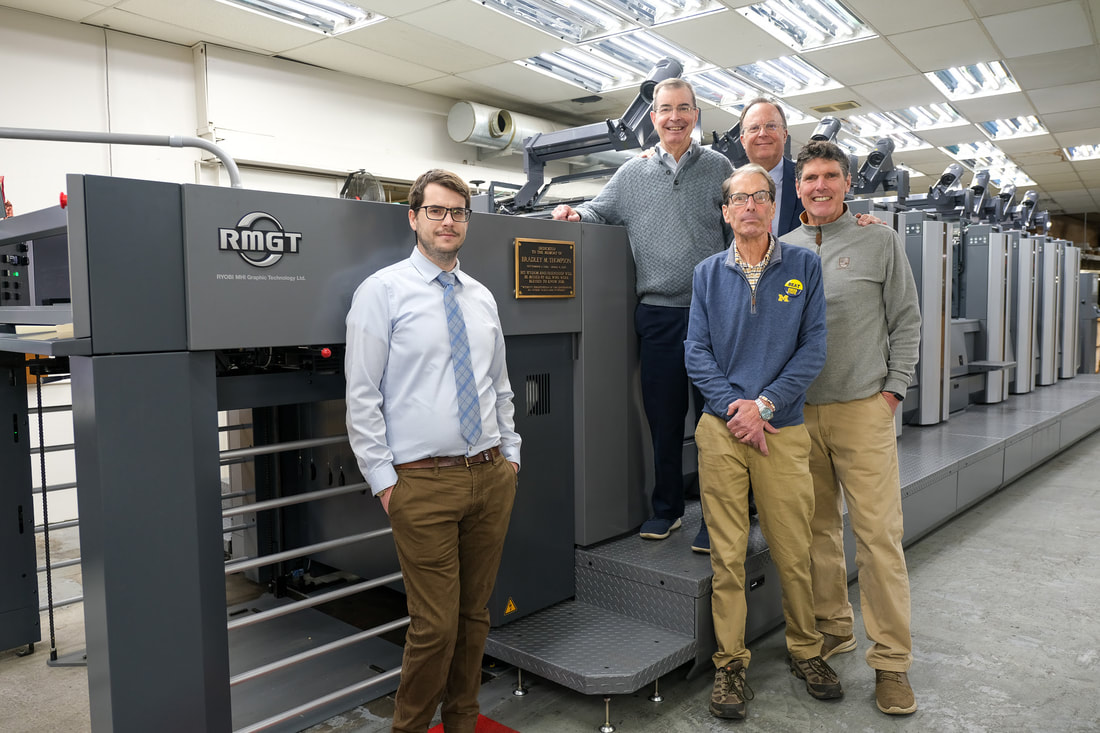

“In past years, printing with a Miller 104, it was at times difficult to keep up with the demand of our clientele, sometimes needing to farm work out to other shops,” he points out. “Since using this RMGT press, we have steadily been gaining on our inventory, even as sales continue to climb. Now, instead of the pressroom being the bottleneck of the operation, we have the agility to take on many more jobs. “We looked for 40-inch presses in the used market, but many of those were nearly half price of this new 970,” concludes Sensenig. “Luke asked this question: ‘What do we gain by buying a half-worn-out press for half the money?’ After more than two years of running nearly wide open every day, [there’s] no question: This was the right decision to go with a new RMGT 970.” If you would like to be contacted with more information on how the RMGT 970 can benefit your business, please fill out the form.Bracing for a frenetic election-printing season, Detroit commercial shop invests in first of its kind ASAP equipped RMGT press featuring LED-UV curing technology. CLEVELAND, OH – January 10, 2024 – Graphco, a leading graphic-arts equipment distributor in the United States, has installed an 8-UP+ RMGT 970PF-8+LED eight-color (four-over-four) perfecting press at Inland Press. A subsidiary of publicly held Detroit Legal News, the 129-year-old general commercial print firm counts automotive and healthcare companies among its clients. In addition, election-related printing represents a sizable chunk of the company’s $10 million in annual sales. Campaigning has already begun for 2024 election season, so installing the new RMGT press quickly after its exhibition at the PRINTING United Expo in Atlanta. “There’s an early presidential primary in Michigan [on February 27th],” explains CEO Brad Thompson, “so we’ve already kicked into high gear.” The pre-ballot action will heat up this summer, he adds, “heading right up to election day in November.” Thompson reports that, in 2022, Inland Press reproduced some 100 million pieces of election materials intended to inform and persuade U.S. voters. The firm’s 45 full-time employees worked two 12-hour shifts, seven days per week. “We were literally running around the clock, with a lot of overtime,” recalls the chief, who has seen myriad changes during his four decades of working in the printing industry. He also is a fifth-generation member of the Thompson Family-run operation at Inland Press. “I guess you could say there’s ‘ink in my blood,’” says Brad, acknowledging his family’s proud legacy. Additional capacity at the plant was necessary because, this year, Inland expects its “political” print runs to jump to between 140 million and 150 million pieces. With that much more ink on paper, job turn-around times “are measured in hours, not days,” he notes. Yet, despite the estimated 40% to 50% increase in volume, Thompson says crew members will achieve their production goals while working shorter (10-hour) shifts than they did two years ago -- and no weekends. Meanwhile, Inland plans to incur minimal overtime charges. How can Inland print 45% more volume in 25% to 30% fewer man hours? Doing more with less“That’s the beauty of the long perfector” and its ability to print double-sided on each sheet, explains Chris Manley, president of Graphco. “Running full-color 8-UP+ printed sheets on both sides at 15,000 SPH in only one pass through the press is a huge production advantage,” he notes. “So from a finished piece production standpoint we are producing at the equivalent of 30,000 SPH on the single sided presses Inland ran last election season.” But the beauty of the 970 platform goes well beyond the excellent production improvement it provides. From a return-on-investment (ROI) perspective, the far better price point should be considered as well. While the RMGT 970PF-8+LED processes the most commonly produced U.S. sheet size of 25” X 38”, it can cost over a $1 million less than a comparable 40” sheetfed-offset printing press. In an apples-to-apples shopping comparison, Thompson says one competing manufacturer’s price was almost double, for a press that prints a sheet 2” wider. Manley adds that an annual debt-service coverage ratio (DSCR) that is $180,000 to $200,000 less can be much less of a strain on RMGT 970 user’s bottom lines. In addition, the press’s faster makeready times are aiding Inland’s quick turns and overall operational efficiency. While it’s still too early for hard-data metrics (the new press only began operating in November 2023), Thompson reports that operators are getting up to color and pulling good sheets much quicker, which results in wasting less paper. “A part of that [enhanced speed] is RMGT’s fully automated plate-changing system,” he points out. From a total cost of ownership (TCO) standpoint, the smaller footprint’s savings on other consumables add up, too. For example, “plates cost 15% less for the 38-inch press,” Manley points out. Plus, with no second operator needed to run the 970, conserving labor cost is an added bonus that passed muster in Inland Press’s unionized shop. Thompson notes: “Needing only a single operator per shift gives us more flexibility to move around skilled personnel. We have had no layoffs,” he stresses. In fact, Inland Press is hiring. Assuring zero defectsInland’s new high-tech press, manufactured by RYOBI Mitsubishi Graphic Technology, features full ASAP (Automatic SMART Assist Program) automation, including state-of-the-art PQS-D-I-R inspection. The addition of this system is important to several customers, Thompson explains, especially those in the automotive and healthcare vertical markets. PQS-D-I-R cameras catch imperfections, such as so-called hickeys, “and do accurate color to within a couple of Delta E,” he notes. The system employs solid-state (CCD) cameras to inspect every sheet for quality, while instantly adjusting color and registration. It tags any sheet in the press delivery that fails the quality inspection so it can be diverted out of the finishing process to provide zero-defect output. “During Phase 2 of the press installation in January, the full ASAP technology package will be added and training will be conducted,” Thompson says. This press configuration marks a first-of-its-kind installation in the United States, which is why the manufacturer “showed off” the model on the floor of the PRINTING United Expo this past October. After the tradeshow in Atlanta, components were packed up and shipped for permanent set up at Inland’s 65,000-square-foot facility, which is situated in Detroit’s historic Corktown neighborhood. ‘Green’ is good: For the Environment & For BusinessEnvironmental sustainability is the proverbial icing on the cake for Thompson and his team at Inland Press. Along with many of their customers, the company is striving to become more ecologically sound and reduce its carbon footprint. “This is the first LED press we’ve had,” he explains, calling the technology a game-changer. “LED curing eliminates VOCs from the pressroom; and the printed sheets are dry when they hit the delivery.” Bindery employees are “ecstatic,” he adds, because instantaneous curing means there is no need for spray powder, which often scuffs and “messes up” sheets.

“Inland’s earnings-per-share numbers for 2024 are extremely aggressive,” Thompson concludes. “A lot of those financial projections are based on our confidence in this new press technology from RMGT and how it will perform. We are excited about the future!” Chris Manley adds, “The new partnership between Inland Press and Graphco makes us extremely proud, and Brad’s Team have been awesome to work with on this new technology implementation. To be part of Inland’s 130th year in business is a great honor, and we can’t wait to see how their new RMGT press will impact their next 130 years.” SOLON, OH – December 12, 2023 – RMGT, manufacturer of the leading 8-UP sheetfed press in North America, announces a very successful PRINTING United Expo by announcing five new printers who have invested in RMGT presses. Reconfirming the strength of the sheetfed offset press market, these investments represent 26 press units that have gone under contract, were announced, or in the case of Inland Press have been installed since the PRINTING United Expo held in Atlanta in October. Emphasizing RMGT’s industry-widest model offering, these new press sales come from every segment of the RMGT product line, including the flagship 8-UP+ 970 Series, the extremely popular 8-UP 920 Series, the 6-UP+ 790 Series, and the space-efficient 6-UP+ 760 Series press. In each case these customers have moved to RMGT from other (mostly German) brands, which continues this market-share shift in the RMGT direction. Also following a sea change trend, each of these presses are equipped with the LED curing technology that was invented for the sheetfed world by Ryobi Graphic Systems back 2008.

GIA PrintingFounded in 1941, GIA Publications, Inc. a family-owned company based in Chicago, IL, is the largest provider of printed sheet music in the United States. Esteemed choral publisher Walton Music became part of GIA in 2013, and both World Library Publications (WLP) and Meredith Music joined the GIA family in 2020. Realizing a long-term goal of upgrading their efficiency, GIA Publishing will replace a German brand 28 x 40” press with a new 8-UP+ four-color RMGT 970 perfector with LED curing. The beauty of the new 8-UP+ 970 is that the super-efficient 25” x 38” sheet size encompasses 95% of the work GIA did on their 40” machine, but their cost of manufacturing will be substantially lower with the new RMGT 970. And with LED the new press will produce 16-page signatures at 15,000 SPH, which compares with running 30,000 SPH on a single-side 40” press. K & M Printing

Southern CompanyThe Southern Company, based in Atlanta, GA, supports 9 million customers and businesses nationwide with electric utilities in three states and natural gas distribution utilities in four states. This industry leading company also provides wholesale energy, customized distributed energy solutions, fiber optics and wireless communications across the country. As part of upgrading their in-plant offset printing operations Southern Company / Alabama Power replaced their existing German press with an extremely compact four-color RMGT 760 sheetfed offset press with LED from Benford UV. Delivering in early 2024, this new press will save 25% in floor space while now producing a 6-UP+ sheet size of 31”x 23.75” versus the 4-UP sheet size offered on their current press. Quick Reliable PrintingCelebrating over 40-years in business, Quick Reliable Printing (QRP), founded in 1979, is a commercial printing company based in Midland, Michigan. Replacing their legacy Sakurai press, QRP upgrades to an 8-UP, four-color RMGT 920 sheetfed offset press with LED curing from Benford UV. This investment in LED technology continues the mission of QRP to support renewable and sustainable environmental choices in print. Adding the 8-UP sheet size to QRP’s already impressive capabilities, will bring tremendous benefits the 2020 Midland Michigan Small Business of the Year award recipient. Recap“Investment in productivity and sustainability are common themes we are seeing with commercial printers, packaging printers, and in-plant operations throughout North America,” states Chris Manley, President, Graphco. “As these companies refresh their aging offset pressroom equipment with state-of-the-art RMGT presses, we are proud to add them to the growing list of printers who have made the switch and joined the RMGT family."

LANDISVILLE, PA – November 9, 2023 – RMGT, manufacturer of the leading 8-up sheetfed offset press in North America, announces that G.E. Richards Graphic Supplies, a leading graphic arts dealer in the United States, in July installed a full-size RMGT 970ST (straight), five-color press at PDC Graphics. The award-winning general commercial print firm in suburban Philadelphia replaced an eight-year-old, half-size RMGT 756 six-color (with coater). The new 970 features an aqueous coater and two LED-UV lamps after the fourth and fifth units.

PDC Graphics’ 30,000-square-foot-plant in Southampton, PA, also added prepress and post-press equipment to keep up with the enhanced productivity of the new eight-up, sheetfed press. The 970 model’s 8-up format is capable of running sheet sizes up to 38 inches. PDC’s business rationale for investing in the new press centers on cost efficiencies. To stay competitive, the company needs the ability to print more of the book, booklet, brochure, catalog and direct-mail advertising work it reproduces -- in the same amount of time. “This full- size press basically makes us twice as fast,” stresses Jim Rosenthal, President and co-owner. The new press technology allows PDC Graphics to grow business by doing more for its existing customer base. “Single sourcing is more and more in demand,” observes Rosenthal, “so this was the next logical step for us, making it easier for customers to do business with us.” Plus, it’s beginning to attract a different type of clientele. PDC now can be competitive on larger quantity jobs of, say, 50,000 copies and more, Rosenthal notes. For high-end work, LED-UV ink printed on uncoated paper “looks brilliant . . . and excites our clients,” he adds. “The colors pop off the page. LED-UV is the future [of printing].” Peak ProductivityForty-four people are employed full-time inside PDC’s 26-year-old facility, generally working two shifts of eight hours each. During peak times, however, the crews ramp up to 10- or even 12-hour shifts, “sometimes seven days a week,” Rosenthal explains. “We get extremely busy during certain times of the year,” he notes, citing the fall benefits open-enrollment season as a prime example. “Many of our customers are involved with benefits onboarding,” continues Rosenthal. “They need hundreds of thousands of employee packets printed for healthcare and insurance-related purposes.” The work adds up: PDC’s sales were up some 10% in 2022 – to approximately $8 million – the president reports. After only three months of production, the PDC team already is seeing more productive results, according to VP and Co-owner Carl Piccari, whose operational focus is more on manufacturing. The new RMGT press’ automation has cut plate-loading times in half: to approximately 10 minutes from more than 20 minutes. “That equates to about 100 minutes daily and 500 minutes weekly,” Piccari points out, “which is almost an entire shift!” In addition, makereadies are faster as RMGT’s console and scanner facilitate maintaining accurate color. “This press ‘learns’ how we want to print,” Piccari shares. As a result, PDC operators are wasting far less paper than the 300 to 500 sheets the older, half-size press consumed when getting up to color. “We have good people, and they’re gaining confidence, going faster and faster,” he notes. “Once maximum performance is achieved, they hope to be ready to go in 50 to 100 sheets.” Prepress and bindery, tooTony Dailey, Sales Manager for GE Richards, adds that a new Kodak ACHIEVE T400 Platesetter in prepress features full automation and internal punching. Complimenting both the pressroom and bindery is a new Toppy Kompressor skid/pile turner and pallet inverter helps PDC to stay more efficient loading paper in and flipping skids at the press, and downstream in the binding/finishing department. Instantly cured ink means printed sheets move quickly from the press into the bindery. “For a 32-page [workflow], we can process and plate two 16-page forms, then fold each,” Rosenthal illustrates, “which means we are setting up two stitcher pockets instead of four.” Changing out cartridges is simplified thanks to a proprietary ink-management system from Sentinel/Pamarco. “The system automatically dispenses the ink from cartridges into the fountains - operators no longer have to climb on the units to scoop out or agitate the ink,” Rosenthal says. “It’s just physically easier.” He also likes the fact that, even though the 970’s footprint is a couple feet longer and 12 inches wider than its half-size predecessor, the full-size configuration still is a single-operator press. “Let’s face the reality,” he says: “Staffing, in general, is an issue, and hiring good people is difficult.” We are lucky – we have an incredible team. This investment is in them and in our future – we wanted to enable our team to be better, and feel better about the excellent job that they do for our customers every day. About RMGT North America

RMGT (RYOBI HMI Graphic Technology Ltd.), a global leader in LED-UV sheetfed offset presses, is represented by a group of four authorized sales and service centers that serve commercial printers, offset packaging converters and in-plant printers in the United States and Canada. Covering the Northeast US is G.E. Richards, Midwest and Southeast US is serviced by Graphco, the Western US is serviced by Print & Finishing Solutions and covering Canada along with the RMGT 10 Series distribution in the US for legacy Mitsubishi customers is RM Machinery. This network constitutes the single largest offset press sales and service team in North America. As innovators of the first LED-UV printing system for sheet-fed offset printing

in 2008. RMGT continues to apply their technological expertise and creativity for constant innovation, providing the printing industry with meaningful products and services while building bonds of trust and respecting diverse values. Learn more about RMGT North America at www.ryobimhi.com Copyright 2023. All brand names are the property of their respective owners and may or may not be trademarked.

SOLON, OH - September 7, 2023 – Last December Graphco and RMGT, providers of the leading 8 UP sheetfed offset press in North America, delivered an RMGT 970 five-color machine (with LED curing) that is producing postcards, booklets, and other products by the millions each month for Range Printing, Inc. in Brainerd, Minnesota. With 9 full months of production under the new fully automated sheetfed device’s proverbial “belt,” the press has become a second “workhorse” in Range’s 36,000-square all RMGT shop floor.

The bottom-line rationale for the new technology investment is that Range Printing needed additional production capacity, according to President/CEO Shawn Sundquist, son of Steve Sundquist and grandson of founder Phil Sundquist, who started the company in 1968. “We wanted redundancy for our ‘commodity’ work to complement our existing RMGT 920 color with coater, which features six color printing, LED and Aqueous coating capabilities and provides the high value-add work that Range is known for in the industry.” “We’ve been running the heck out of that 920 for more than five years now, piling up well over 100 million impressions,” reports Sundquist. The firm, which employs roughly 70 people (on two shifts), tallied 2022 sales of approximately $14 million. “We are actively looking to grow by acquisition,” Range’s chief executive added. After a slow beginning to 2023, attributed to the sluggish U.S. economy and rising inflation rates, its two press schedules started filling up in mid-May and running strong all summer long. On the new RMGT 970, Range is running 6x9” postcards as well as 9x12” booklets. “The bigger, 25” x 38” sheet size has more ‘real estate’ and lends itself to this type of work,” Sundquist noted. “We can go 6-up [on a sheet] for the millions of 12x12” scrapbook pages we print annually on both coated and uncoated paper. Our customers love the crisp LED print we produce on uncoated jobs.” The micro-orders that make up this huge volume come through Creative Memories, which is a fellow Minnesota corporation and 15-year partner with Range. With a reputation for offering high-quality scrapbook products, Creative Memories pioneered the memory-keeping industry in 1987. Scrapbook hobbyists, looking for something to do at home during the 2020-21 pandemic lockdowns, were a welcome silver lining in the dark, dreary clouds cast by COVID-19. Range prints some portions of these popular jobs digitally on its HP Indigo presses, but the much lower costs and higher print quality of the RMGT produced jobs are key advantages. Coverage, Color and Versatility Derek Gordon, Midwest Regional Manager at Graphco, stated: “The RMGT 970 press gives Range Printing the versatility to reproduce diverse products, including the booklets and packaging applications that feed Range’s high-speed die cutter. Shawn has told us that his press crews particularly appreciate our Benford LED curing system, since they have no dry-back and they can ship our vibrant color jobs on all substrates without waiting.” “The LED cures from the top down,” Sundquist explains, and adds that ink coverage never has been a problem for his RMGT presses. He and his Range employees have noticed the manufacturer’s “tech refresh” on the 970 model press. “The RMGT engineers have made a lot of modifications and improvements that really improve our throughput and ease-of-use,” he observed. Another benefit comes by way of a closed-loop, LithoFlash color-control system, from Lithec USA, that was added to both presses during this investment cycle. The in-press system is saving Range money by yielding less paper waste, maintaining super-tight color tolerance throughout the run and allowing pressmen to run full speed without worries. “We can get up to color now in 100 to 150 sheets. Our average makeready times between jobs has dropped from 15 minutes on the 920 to 10 minutes on both presses with the LithoFlash system,” reported Sundquist. “It was a huge plus that Graphco was also able to add LithoFlash to our existing RMGT 920ST six with coater. I sure was glad this major upgrade didn't require a forklift,” adds Sundquist. This, of course, means that Range can churn out more work, which is the key to sustaining profitability in today’s competitive commercial print landscape, and all while avoiding the added expense in equipment costs, supplies and labor associated with a 40” press. “Once we learned that we could do 9x12” publications, 6x9” postcards, and our 12x12” scrapbooking jobs on the 25” x 38” sheet we saw no reason to go back to the 28” x 40” format,” confirms Sundquist. “We fully recognize that Shawn coming with Graphco and RMGT back in 2017 was a big leap,” comments Chris Manley, President, Graphco, “since Range was coming from decades of investments with one of our main competitors. As a fellow business owner, it’s rewarding that he and Mary decided to continue our relationship. Additionally, as fellow SOBs (sons of the boss) I am so glad to be part of Range Printing’s third generation in our industry. Shawn and Mary’s sons are keen on Range as well, so there are many chapters left to be written up in Brainerd.”

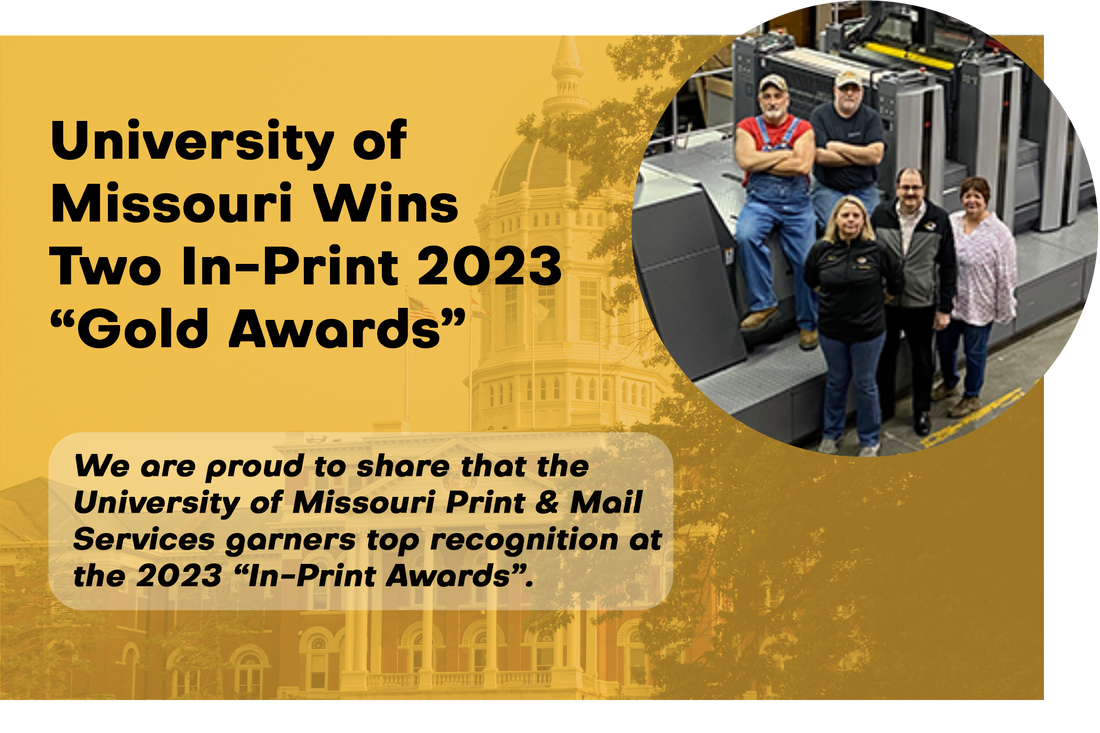

University of Missouri Print & Mail Services garners top recognition at the 2023 “In-Print Awards.”

SOLON, OH – May 24, 2022 – In 2019, Graphco, distributor of the industry leading eight-up sheetfed offset press in North America, provided an RMGT 940 five-color press (with coater and LED-UV curing unit) that was used to produce two Gold Award winning pieces for the University of Missouri at the 2023 In-Print Awards competition. The annual contest, co-sponsored by the In-Plant Printing & Mailing Association (IPMA) and In-plant Impressions magazine, is held exclusively for in-plant shops from across industry segments. The University of Missouri faced stiff competition from several other large U.S. universities along with other contestants. (View the complete list of 30 winners.) Capturing gold in the “Booklet” category, the large-format Viewbook is used to help recruit prospective high-school seniors (and their families) to the University of Missouri. “We mail it as a periodical to optimize postage rates,” explained Jeff McNeeley, Director of the University’s 50,000-square-foot print/mail operation, which employs 33 people. The four-color publication features spot high-gloss varnish on the cover and is saddle-stitched in the bindery. MU Health, as the “Magazine/Catalog” category winner, is also printed 4/C, saddle-stitched and mailed to a different audience: the University Medical System’s healthcare patients. Derek Gordon, Midwest regional manager at Graphco, stated: “We are proud to play a part of the University of Missouri’s success. The large runs of 100,000 and 50,000 copies [see specs, below] are above their norm—since they average 3,000 and 5,000 impressions per run – but it’s no surprise that their RMGT press brought home the gold!” Additional job specifications:

“We love the fact that the jobs come off our press dry and we can finish immediately,” continued McNeeley, who, along with his press crew, has fully transitioned from conventional to LED-cured inks on their 8-up offset press. “With the right ink sets and G7 profiling, our colors are extremely consistent. RMGT’s Insta.Color system is closed-loop, and we are dialed in now. There was very little variance on that 100,000, multiple-day Viewbook run,” he said, adding that one of the school colors is gold (PMS 124), which can pose a challenge. “It’s really more of a reddish yellow, which we build from CMYK to match -- and need to maintain extremely tight tolerances for Mizzou branding purposes.” From a bottom-line, machine ROI (return on investment) standpoint, the RMGT’s fast printing speeds (>15,000 sheets per hour) and substantial paper savings enhance overall production efficiencies for the award winning in-plant printer. “Makereadies are just more efficient,” McNeeley reported. University of Missouri press operators confirm that their RMGT Full Autoplate system changes all 5 plates in less than 3 minutes and they now use much less waste paper on their 9 Series press. “That’s a huge drop from our traditional 40” press, which was over 20 years old and would need about 1,600 waste sheets per run. So, essentially, we are able to makeready in half the time, and run 42% faster. A win-win for our operation,” he concluded. These Gold Category winners, along with all the others can be seen at the IPMA annual conference being held on June 4-8, 2023 in Bonita Springs, FL. For more information, go to https://ipma.org/ipma-2023-conference.

About Graphco

Graphco is the industry’s leading provider of offset, digital, and print finishing solutions. We proudly represent the finest brands of equipment including RMGT (Ryobi MHI Graphic Technology), Benford LED-UV, Konica Minolta, Standard Horizon, CRON-ECRM, Graphic Whizard, Petratto, Spiel Associates/Sterling, MBM, and many more. These brands are only as good as the technical support team that stands behind them and Graphco’s reputation for top-notch service is second to none. Since 1976, Graphco has thrived in an ever-changing marketplace by loyally adhering to the firm’s original model for success: providing best-in-class print production equipment along with reliable and assured technical service. Learn more about Graphco at www.graphco.com, 800-458-2769. Copyright 2023. All brand names are the property of their respective owners and may or may not be trademarked.

PLACENTIA, CA – May 17, 2023 – RMGT, manufacturer of the leading 8-up sheetfed press in North America, this past summer installed two new offset machines to state-government agencies in Austin, TX. In June, a 29-inch, four-color 790 model perfecting press was delivered to the Texas Health and Human Services (HHS) in-plant facility. Two months later, the Texas Department of Transportation (TxDOT) took delivery of a four-color, 25.2x37" RMGT 940ST offset press with an LED-UV curing unit, replacing its 4-color Ryobi 754G XL, which was seven years old.

“These recent press installations, at two autonomous facilities, offer concrete proof that offset printing is far from dead at in-plant shops,” believes Kian Hemmen, sales director of RMGT Print & Finishing Solutions. “Challenged by labor shortages from staff retirements, many in- plant operations are realizing the efficiencies that advanced automation and larger sheet sizes can bring. The return on investment is there.” Texas DOT sees benefit of LED-UV curing One of the outstanding features of the new RMGT 940ST is the LED-UV curing unit, which instantly dries printed sheets. “It doesn’t matter how much ink coverage we have. We print it and it’s dry. The job can move immediately to the bindery,” remarks Art Garcia, Production Manager, Texas DOT. “Additionally, there are no worries about ink offset on the sheets, so the operator can let printed sheets pile higher without having to stop periodically to remove them. Instant drying also means the press does not need to use powder, which reduces clean-up time. We don’t have to do as much maintenance,” affirms Garcia. Another major improvement with the RMGT 9 Series press is the larger sheet size. The new press enables TxDOT to run 16-page and even 32-page signatures, so it can take on more publications work. Garcia estimates productivity has increased 50% just because of the larger sheet size. With a larger sheet size enabling the shop to expand the types of work it can produce, and an LED-UV curing unit that instantly dries printed sheets, the new 15,000-sheet-per-hour (sph) press has stepped up productivity at TxDOT’s 130,000-square-foot plant. Substantial production efficiencies are what led both agencies to justify procuring conventional printing equipment.

“Automatic plate changing as well as auto blanket and ink-roller cleaning expedite the 790’s makeready times,” noted RMGT’s Hemmen. “In addition, programmable inking speeds up tone adjustments.” The press also features continuous dampening and print-density control systems.

Kida admits to considering digital press options before recommitting to an offset solution. “We did our homework,” he shared, which included weighing pros and cons of the latest production inkjet printing technologies. As part of HHS’s due diligence process, he visited TxDOT to see a RMGT 7 offset model in action. “I also checked out an eight-color version at a local commercial printer,” he said. “Both sites offered positive feedback about their respective RMGT presses.” About RMGT North America RMGT (RYOBI HMI Graphic Technology Ltd.), a global leader in LED-UV sheetfed offset presses, is represented by a group of four authorized sales and service centers that serve commercial printers, offset packaging converters and in-plant printers in the United States and Canada. Covering the Northeast US is G.E. Richards, Midwest and Southeast US is serviced by Graphco, the Western US is serviced by Print & Finishing Solutions and covering Canada along with the RMGT 10 Series distribution in the US for legacy Mitsubishi customers is RM Machinery. This network constitutes the single largest offset press sales and service team in North America. As innovators of the first LED-UV printing system for sheetfed offset printing in 2008. RMGT continues to apply their technological expertise and creativity for constant innovation, providing the printing industry with meaningful products and services while building bonds of trust and respecting diverse values. Learn more about RMGT North America at www.ryobimhi.com Copyright 2023. All brand names are the property of their respective owners and may or may not be trademarked.

|

Categories

All

Archives

June 2024

Follow |