RMGT’s exhibits and demonstrations will focus on two major concepts: “Increased productivity for commercial printing through autonomous operation,” and “Further automation for package printing."

On display for the commercial print market and the packaging market will be the 8-UP+ size RMGT 970PF-8+LED convertible perfector, which is also available in straight configurations up to 8 colors, perfectos up to 10 colors and all presses are available with inline coating. New generation skeleton cylinders, and the most comprehensive automation packages available all contribute to the RMGT 9 Series press continuing to lead the 8-up sheetfed offset press market in North America.

Visit us at Hall 16 / E11 to chat with our knowledgeable staff, see our RMGT 9 Series Press running live, and learn more about the benefits of RMGT technology and the future of offset printing!

On display for the commercial print market and the packaging market will be the 8-UP+ size RMGT 970PF-8+LED convertible perfector, which is also available in straight configurations up to 8 colors, perfectos up to 10 colors and all presses are available with inline coating. New generation skeleton cylinders, and the most comprehensive automation packages available all contribute to the RMGT 9 Series press continuing to lead the 8-up sheetfed offset press market in North America.

Visit us at Hall 16 / E11 to chat with our knowledgeable staff, see our RMGT 9 Series Press running live, and learn more about the benefits of RMGT technology and the future of offset printing!

|

Register for a personalized VIP Demo at drupa!

|

|

What we will showcase at drupa:

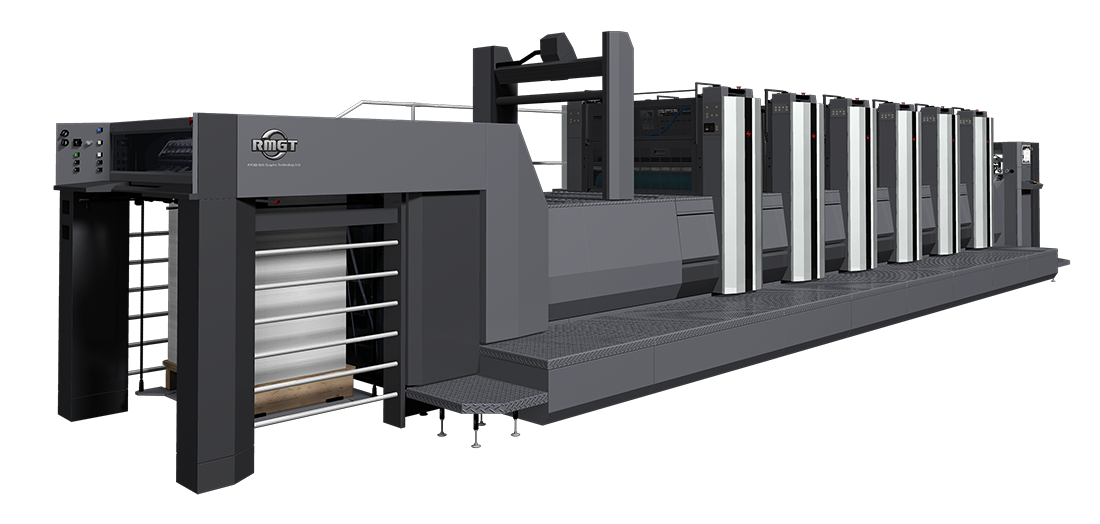

RMGT 970

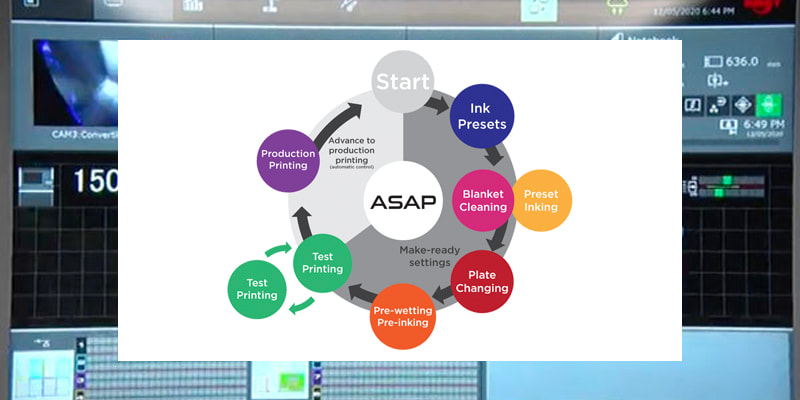

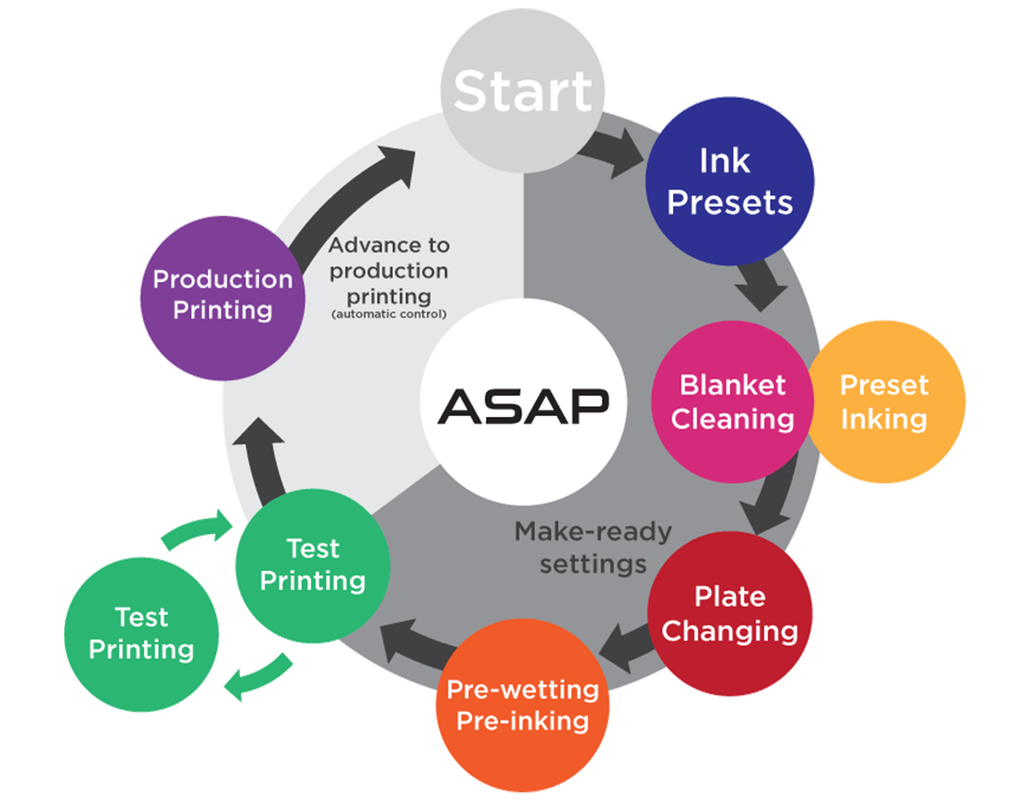

Capable of handling the world’s most popular A1-plus size, the 970 offers major cost advantages. This next-generation A1-plus size press is equipped with an array of advanced automation functions for assisting the operator, including Smart Assist Printing for automatic continuous printing of multiple jobs. Demonstrations will include continuous printing of two jobs using Smart Assist Printing, highlighting the higher operating rate for commercial printing as well as operation by entry level operators made possible by the 970’s automation functions.

|

● A perfecting device ensures stable paper transport and reversing even during high-speed printing, and an LED-UV curing unit* enables one-pass instant-drying perfecting

● A Smart-FPC fully automatic simultaneous plate changer with benderless plate clamp for quick job changes*, and a predictive control system quickly achieves the target density ● A PQS-D (I+C+R) printing quality control system checks the quality of every printed sheet* ● Automatic continuous printing of multiple jobs is made possible using Smart Assist Printing in combination with the PQS-D printing quality control system* *Option |

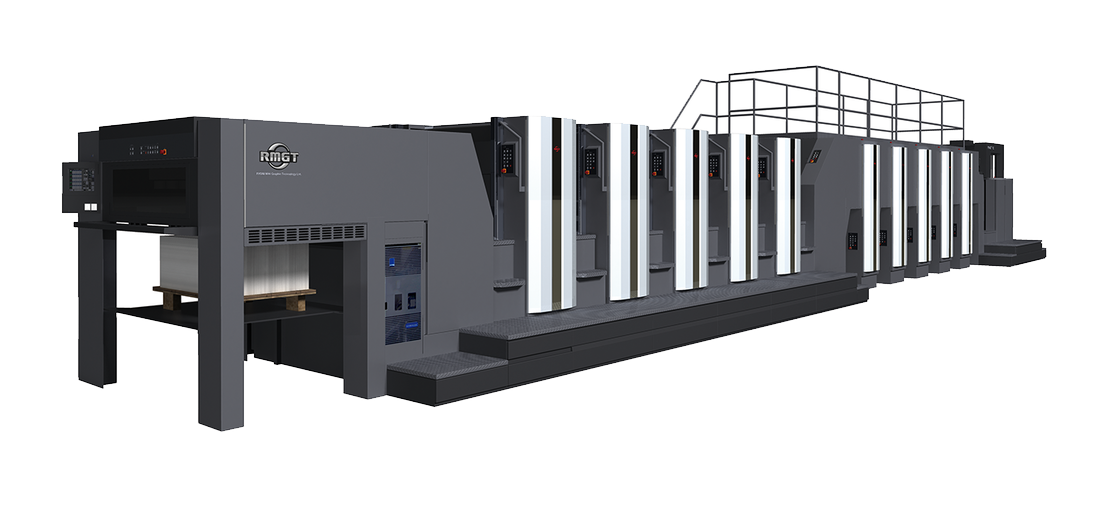

RMGT 1060

The 1060LX is an upgraded model that offers improved paper feed and delivery performance and a much shorter make-ready time during job changeover, significantly boosting productivity for package printing. The 1060LX’s advanced features, which greatly boost package printing productivity through continuous operation and speedy job changeover, will be demonstrated using two printing images with special colors and coating varnish. The 1060LX is an upgraded model that offers improved paper feed and delivery performance and a much shorter make-ready time during job changeover, significantly boosting productivity for package printing. The 1060LX’s advanced features, which greatly boost package printing productivity through continuous operation and speedy job changeover, will be demonstrated using two printing images with special colors and coating varnish.

|

|

● Continuous operation using an automatic nonstop feeder and delivery shutter*

● High-speed package printing of 17,100 S.P.H., including the use of a polygon-type vacuum wheel at the delivery section and enhanced feeder-and-registration section functions that increase the printing speed for heavy stock* ● Simul Changer fully automatic simultaneous plate changer for fast job changeover, and a retractable coating unit (with a semi-automatic plate changer) that enables preparation for varnish coating to be performed while printing* ● Instant-drying printing using an LED-UV curing unit; capable of high-value-added printing such as chemical embossed printing* *Option |