Need more information?The release of the new ASAP system will allow RMGT customers to enjoy an entirely new level of automation and autonomous press operation in the 8 UP+ press format.

|

|

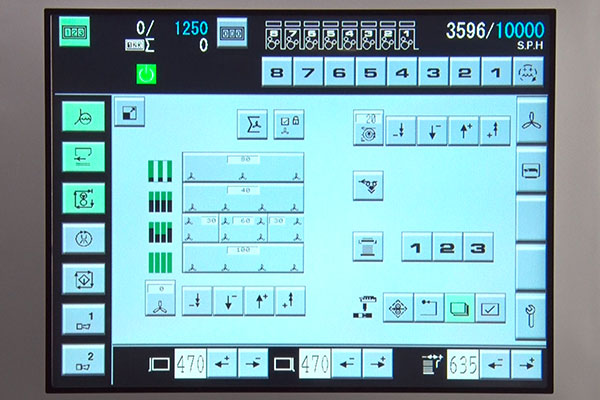

New Streamlined User InterfaceFeeder and delivery section touchscreen panels

Various feeder section operations, settings and checks can be performed via a touchscreen panel, including starting a print run, the counter settings, feeder air presetting*, and feed timing checker. Delivery section settings such as adjustment of the back guide and side guide as well as adjustment of the delivery fan volume are also performed via a touchscreen panel, greatly simplifying delivery section tasks. Both operation panels are equipped with error description displays and other monitoring functions to assist the press operator *Optional |

Delivery fan volume adjustment screen

|

Digital Workflow

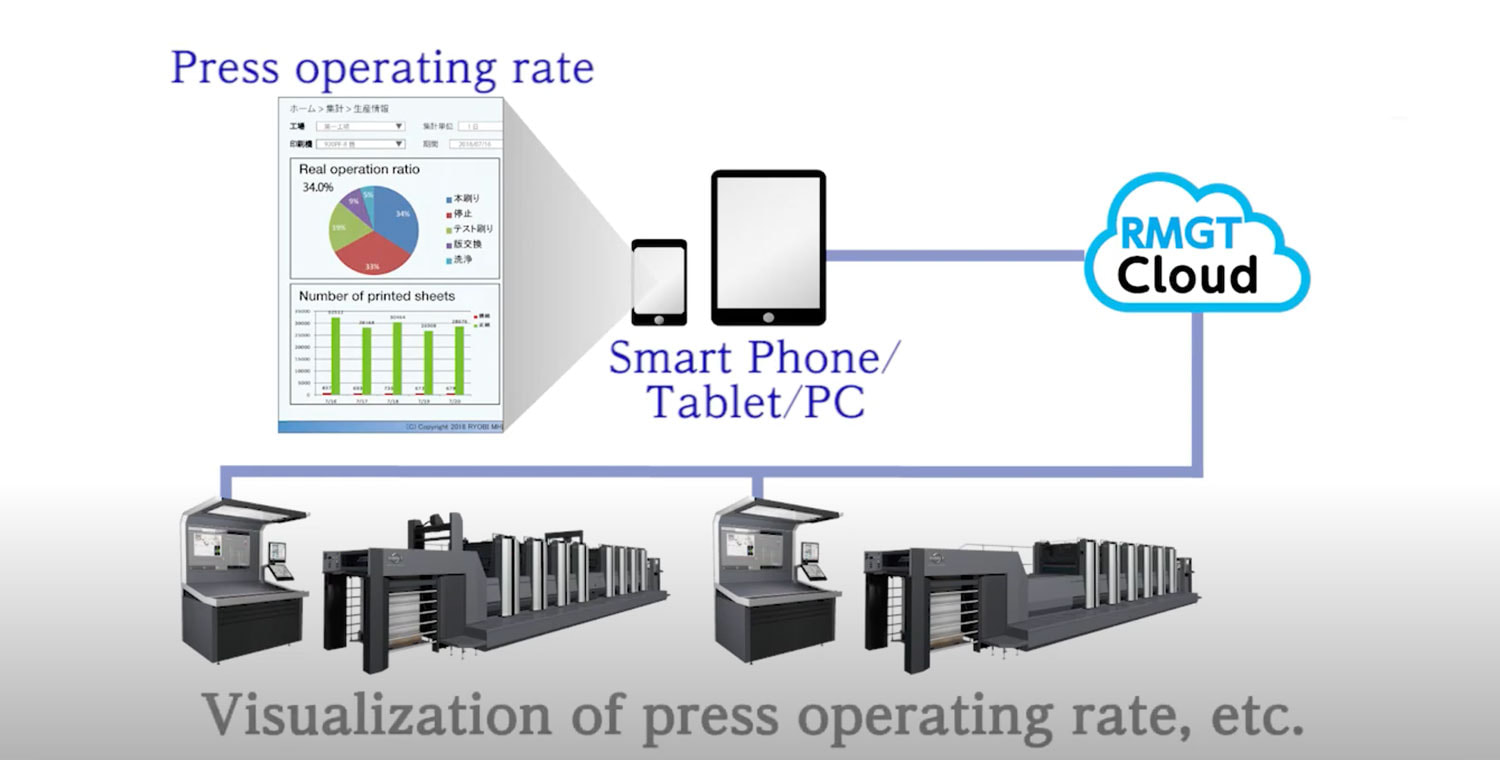

A digital workflow can be established to integrate the entire press room, prepress, and other internal sections. With the IPC and PPC servers as an interface, you can not only implement MIS, CIP4 and JDF, but also easily connect to other management systems and prepress processes you have established separately.

|

MIS connection software {CIP4-JDF)*

MIS connection software connects a CIP4-JDF compatible MIS (Management Information System) and PCS-G printing control system for real-time printing process management. |

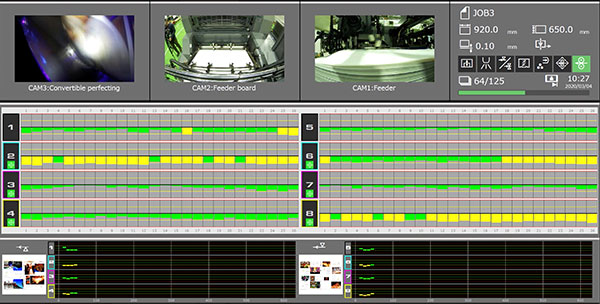

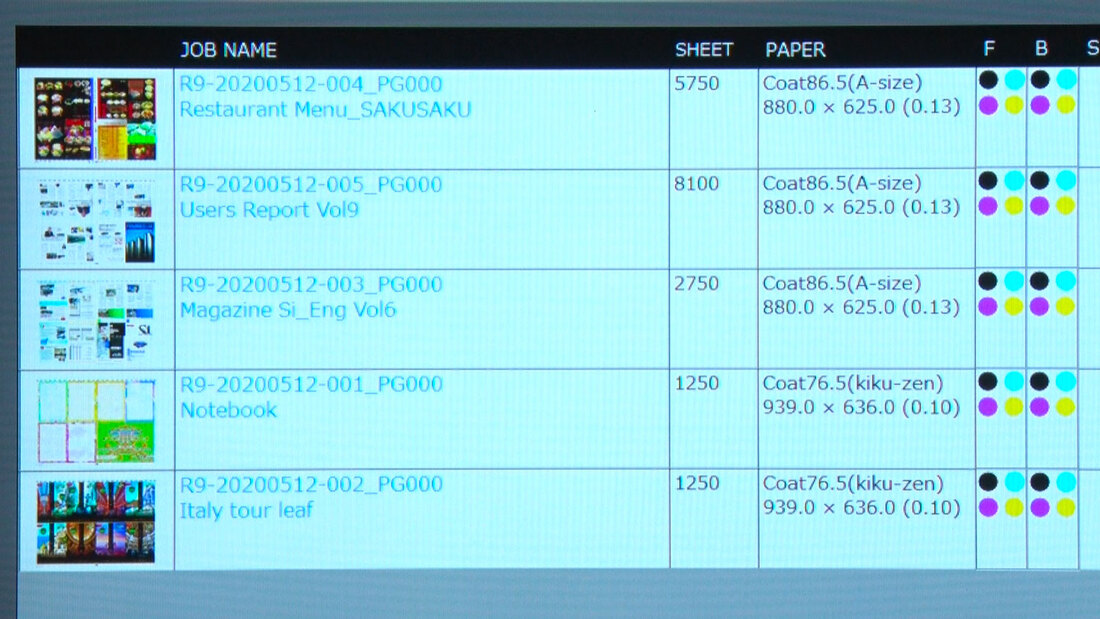

Print Job Manager*

The optional Print Job Manager press operation control system connects compatible presses via a network to manage the production schedule and transmit printing job data. It also collects data on press operating status in real time and automatically generates production analysis data. |

PPC Server (PPC Server III)*

This server converts image area ratio data generated by CIP3/CIP4-PPF and CIP4-JDFenabled prepress systems and provides data on ink key opening volume. |