|

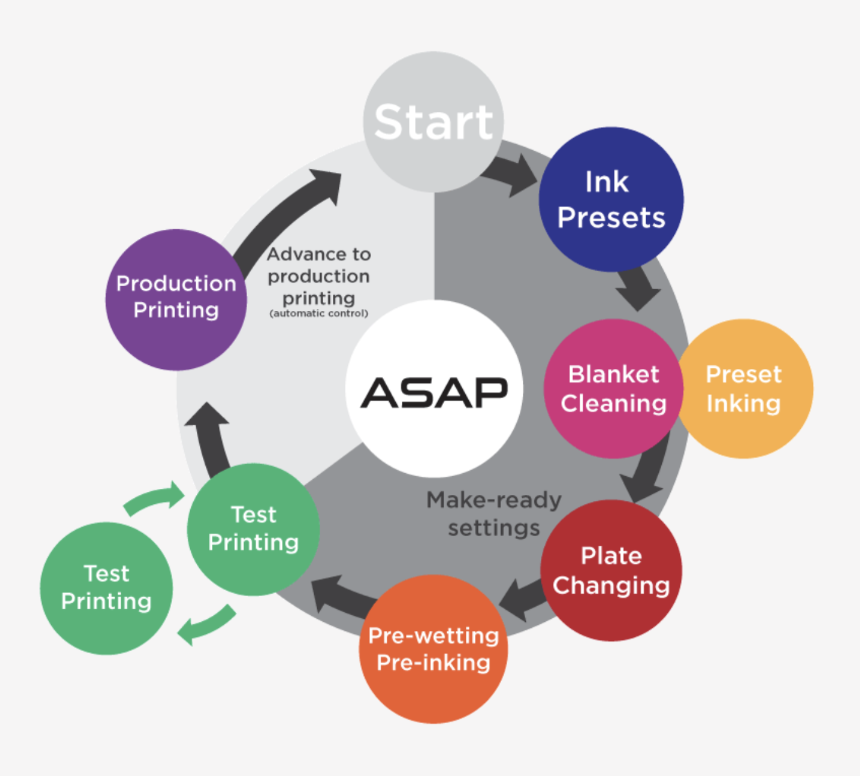

The release of the new ASAP system will allow RMGT customers to enjoy an entirely new level of automation and autonomous press operation in the 8 UP+ press format.

Automated Smart Assist Printing increases press operating rates for continuous printing of short-run work Smart Insta.Color technology has proven itself with fast makeready times for many years, and the release of the new ASAP system will allow RMGT customers to enjoy an entirely new level of automation and autonomous press operation in the 8 UP+ press format. With ASAP the pressman touches one button and the entire printing process—from ink and paper presetting, blanket and impression cleaning, and plate changing through verification of test printing, register adjustment, ink density adjustment, and full sheet inspection are all autonomously processed by the ASAP system without even pulling a sheet.

Fill out the form to receive more information on the RMGT 970 offset press!

Hagg Press Adds Second RMGT Press in Four Years

|

|

Fill out the form to receive more information on how your company can benefit from the RMGT 970 press!

|

|

Keystone Folding Box Celebrates First Year with RMGT 970 Press

25” X 38” sheet format and LED-UV curing prove to be the ideal paperboard packaging print solution for Keystone’s high quality pharma folding carton products.

“With a maximum speed of 16,000 an hour, we're really seeing the results that are coming through on this press” says Wade Hartman, President of Keystone Folding Boxes, Inc. The recent addition of the RMGT 970 press to this New Jersey-based folding carton company has supported its continuation of business growth. A small boutique printery, Keystone Folding Boxes needed a printer with more capacity for printing while fitting within the company’s limited space. The RMGT 970 is able to fit a small section of shop while being gaining 100% of the performance of a larger printer just by having a little bit smaller screen size format.

“The LED curing is super fast, the jobs are coming out reliable, the print quality is just what we expect. We already have two Mitsubishis and this fits right in with that, but it's saving us power on the LED curing and we're getting excellent performance with it.”

-Wade Hartman

Since the start of operating the RMGT 970 press in January, Keystone reported that they have been increasingly routing more and more jobs to it thanks to the efficient results of this printer.

RMGT, manufacturer of the leading 8-up sheetfed press in North America, has installed a RMGT 970 offset printing press at Keystone Folding Box Co. Based in Newark, NJ, Keystone designs and manufactures folding cartons, capsules, blister cards and other packaging for customers in the healthcare field. The privately held company, which owns two other Mitsubishi/RMGT presses, is celebrating its 115th business anniversary this year.

“Much of the clinical trial and medical device work we do is quick turn,” explains Wade Hartman, President, Keystone Folding Box Co. “The new RMGT 970 runs fast at speeds exceeding 15,000 sheets per hour.” After 12 full months of operating the 25” X 38” size machine, Hartman reports that he could not be more pleased with its quality, speed and overall performance for the pharmaceutical packaging materials in which his firm specializes. “We keep sending more and more jobs to the 970,” Hartman reports.

Keystone intentionally chose the RMGT 970 press for its compact footprint which is ideally suited for its 50,000+-square-foot facility in New Jersey. “We have some floor space constraints,” admits Hartman, “but we were able to get this press into a tight space while still getting the excellent print quality we expect along with fast job turnaround times. Being able to print up to 24-point board on a 25 x 38-inch sheet, the RMGT 970 has 100% of the performance of a larger press.”

Exceptional cost performance increases profitability

Adding capacity has been another benefit of Keystone running the 970 model, adds Lloyd Molloy, director of customer service at equipment distributor RM Machinery (RMM). “The LED-UV curing technology has opened up their finishing and die cutting departments,” Molloy says, “facilitating overall growth for the firm in 2022.”

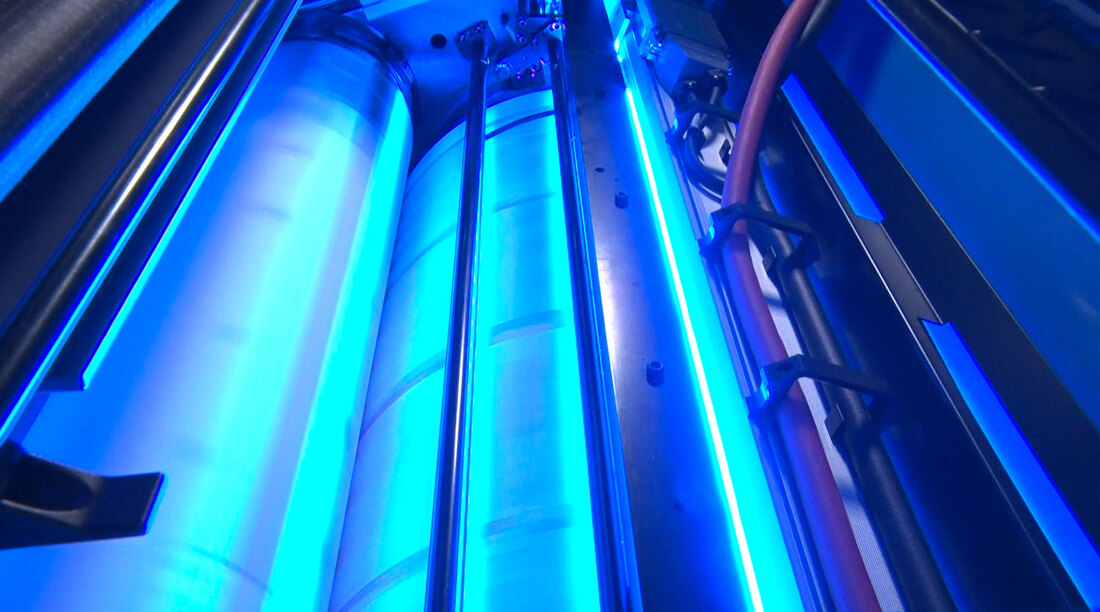

Light-emitting diode, ultraviolet curing units at the perfecting and delivery sections allows for instant drying at maximum press speed -- eliminating the need to wait before proceeding to postpress processes and satisfying the demand for shorter lead times. Keystone recently added a Bobst Expertcut 106 PER to their state-of-the-art die cutting operations. “The LED-UV provides instant curing off the press,” observes Hartman, “and, it is saving us money since it uses less power.”

Compared to 40-inch format presses, the 970 model has substantially lower plate costs and markedly lower power consumption. Research conducted by RMGT reveals that plate costs are reduced about 20%, power consumption by about 34% and installation space by about 30%.

Introduced in mid-2020, the RMGT 970 model lineup includes straight printing presses and convertible perfectors ranging from two to 10 colors. Coating units can also be installed. Large-capacity feeder and delivery piles as well as the newly designed larger cylinder diameters enhance printing capability on heavy stock.

“RMGT had a very successful PRINTING United with 49 press units going under contract during the show,” states Kian Hemmen, Director of Sales, Print & Finishing Solutions, “All four of our regional sales and service centers in North America had offset press sales in both the commercial print and packaging segment across the country.”

Another commercial printer who continues to invest in offset print is EZ Mailing, based in Indianapolis, IN. “EZ Mailing decided to “double down” in Las Vegas, adding a second RMGT press to their operation,” states Gary Greis, Regional Sales Manager for Graphco. “They invested in a new RMGT 9 Series 8-color perfecting press with LED-UV curing. Kevin Bennett, President of EZ Mailing comments, “Our first RMGT took our company from $3 million to north of $9 million this year, so we can hardly wait to see what this new long perfector will do for us and our customers.”

“PRINTING United satisfied a pent-up demand among printers to see the latest in printing technology,” states Jeff Wagner, President, G.E. Richards, Northeast Distributor for RMGT. “With our press running live demonstrations every hour of the show, we highlighted the new reality of how the gap of short run print jobs has shifted from digital back to offset. Additionally, the new 8-UP+ RMGT 970 joins the successful 9 Series family of offset presses from RMGT that are the North American 8-up market leader in bridging the gap between a half size press and 40-inch press.”

RMGT Sponsors ELITE LED User Group Meeting & State of the Industry VIP Keynote at PRINTING United

10/12/2022

RMGT, the leading provider of LED-UV curing technology for sheet-fed offset presses since 2008 announces the RMGT ELITE LED Users Group will meet on Thursday, October 20, 2022, at PRINTING United. RMGT also announces their proud sponsorship of the State of the Industry presentation by PRINTING United Chief Economist, Andy Paparozzi. This highly anticipated industry highlight will take place at the Keynote Theater on Wednesday, October 19, 2022, at 1:00 pm during PRINTING United in Las Vegas.

This year’s RMGT ELITE LED User Group meeting will focus on Sustainability of LED Print, and will be held in the RMGT booth, N801. The program starts at 9:00 am on Thursday, October 20. Gary Jones, Director, Environmental, Health, and Safety Affairs, PRINTING United Alliance will kick off the program with an update on how governmental regulations regarding sustainability will impact printers in the US. The keynote session will provide

attendees with an opportunity to hear directly from ELITE RMGT LED users as they share their experience with all aspects of LED print production. RMGT was the first offset press manufacturer to develop and introduce LED-UV curing technology to the offset press market starting at Drupa 2008. 2022 marks the 14-year anniversary of this revolutionary change in Print Technology. To learn more and register for the ELITE RMGT User Group Meeting please visit: https://www.ryobimhi.com/elite-users-group-2022

On Wednesday, October 19, at 1:00 pm, Andy Paparozzi, PRINTING United Alliance Chief Economist, will recap the State of the Industry during his presentation. Shining the spotlight on real world example, Andy will lead a panel discussion with printing companies who have grown profitably despite the challenges facing our industry. Featured in the panel discussion will be Rudy DeSousa, VP Sales at Pioneer Press, a major commercial printer in Denver, CO who recently acquired an LED equipped RMGT 920PF-8+CC eight color perfector with in-line coating. Attendees will learn what to do right now to build revenue, control costs, and get on the leading edge of the market redistribution that is currently underway.

RMGT, manufacturer of the leading 8-up sheetfed offset press in North America, announces that they will be running live print jobs at the PRINTING United Expo 2022. RMGT has been running live press runs at major trade shows since 2015. As a featured stop on the “Commit to Print” World Tour, RMGT will launch their new 8-UP+ RMGT 970 offset press at PRINTING United, the largest gathering for printers in North America held at the Las Vegas Convention Center on Oct. 19-21.

With the press running live demonstrations every hour of the show, RMGT will highlight the new reality of how the gap of short run print jobs has shifted from digital back to offset. Additionally, the new 8-UP+ RMGT 970 joins the successful 9 Series family of offset presses from RMGT that are the North American 8-up market leader in bridging the gap between a half size press and 40-inch press.

“We are excited to include the PRINTING United event in Las Vegas as part of the RMGT Commit to Print World Tour,” states Chris Manley, President of Graphco, Midwest and Southeast Distributor for RMGT. “RMGT’s commitment to live press demonstrations during large industry events continues in 2022 with the North American launch of our new 8-UP+ RMGT 970 offset press. Our ability to install a four-color, 8-up press for a three-day show is testimony to one of the additional benefits of the RMGT 9 Series press: the smallest footprint of an eight-page sheetfed offset press in the industry.”

About RMGT North America

RMGT (RYOBI HMI Graphic Technology Ltd.), a global leader in LED-UV sheetfed offset presses, is represented by a group of four authorized sales and service centers that serve commercial printers, offset packaging converters and in-plant printers in the United States and Canada. Covering the Northeast US is G.E. Richards, Midwest and Southeast US is serviced by Graphco, the Western US is serviced by Print & Finishing Solutions and covering Canada along with the RMGT 10 Series distribution in the US for legacy Mitsubishi customers is RM Machinery. This network constitutes the single largest offset press sales and service team in North America. As innovators of the first LED-UV printing system for sheet-fed offset printing in 2008. RMGT continues to apply their technological expertise and creativity for constant innovation, providing the printing industry with meaningful products and services while building bonds of trust and respecting diverse values. Learn more about RMGT North America at www.ryobimhi.com

RMGT, manufacturer of the leading 8-up sheetfed offset press in North America, announces the installation of the 4-color RMGT 9 Series offset press with LED-UV curing technology at DavCo Advertising. This multi-generation, family-owned business was founded in 1974 by David Esh, then a veteran salesman of promotional products who had a side interest in printing. DavCo Advertising has expanded the legacy of promotional products to include apparel and a commercial print and mailing fulfilment operation that occupies a 60,000 square feet production facility in Kinzers, PA.

“We were very fortunate to see our business grow during the most recent pandemic,” states Don Esh, Vice President, DavCo Advertising. “As some of our national clients increased their print volumes, we needed to add another 8-up press to keep up with demand. We found a trend building for high end work on uncoated stocks. So it became apparent to us that we needed to move to the more efficient LED-UV curing. Since we could get 8-up production without having to invest in a 40-inch press, the RMGT 9 Series press with LED-UV curing was a perfect solution for us.”

Adding LED-UV curing to this RMGT 9 Series press has allowed DavCo to gain efficiencies that contribute to their bottom line. Since UV inks cure instantly by LED lamps in the press, not only do they find a savings in electricity, but jobs can move immediately into finishing. Once the printed sheet moves into post-press, the absence of powder in the pressroom has additional benefits.

“LED-UV curing allows us to eliminate the use of powder in the pressroom,” states Esh. “We find that our finishing equipment runs much more efficiently. In addition, we often print shells using our RMGT 9 Series press and then run the cut sheets through our digital press production for variable data printing or addressing for mailing. Without powder buildup on the rollers, these digital presses run much more effectively.”

“We have had Ryobi presses for over 30 years,” observes Merle Esh, VP Sales and Marketing, DavCo Advertising. “When we expanded our commercial print operations in 2014 and then again this year, it was only logical for us to continue with RMGT and with G.E. Richards, who have provided stellar sales and service support over these many decades.”

“We were especially pleased to have DavCo host a stop on the RMGT 2022 “Commit to Print World Tour”, states Jeff Wagner, President, G.E. Richards, Eastern US Distributor for RMGT. “Beyond the fact that this is the second RMGT 9 Series press purchased in the last seven years by DavCo, our organizations share a kinship of being family owned and operated businesses in central Pennsylvania. Our mutual success is something we are very proud of.”

Pioneer Press, a leading commercial printer in the greater Denver, CO market will be installing an eight-color RMGT 9 Series perfecting press with LED-UV curing, this summer. Based in Greeley, CO, Pioneer Press has been in business for over 45 years, with the current ownership in place since 1999. The installation of the eight-color RMGT perfecting press will upgrade their capabilities, producing an increase in production efficiency of 300%. This will be the first LED-UV press of this size in the state of Colorado.

“After my father and I purchased the company in 1999, I started by working directly with and for production so I could learn all the processes we were asking our employees to perform,” states Cris SoRelle, President, Pioneer Press. “As my role in the company evolved this allowed me to realize that technological advances can significantly impact production capabilities. One of the skills I brought to the company was my understanding of analytics. I upgraded our estimating system so that we had a better understanding of our true costs. The knowledge gained from the new system allowed us to be more competitive, and we tripled our business. We have been fortunate to have a business that is very stable even during difficult economic times and we have been able to grow through these times.”

Pioneer Press has been able to leverage technology to create efficiencies for its customers. “We won’t always be the first company over the wall, but we sure won’t be far behind!” states Bob Shoemate, Vice President of Operations. “As soon as a technology proves itself, we are right there, from automating pre-press, online storefronts that implement web-to-print, and even our digital printing capabilities. When it came time to buy a new press, we went with the most current and proven technology that offers the greatest rewards to both, our production team and our customers and that was clearly, the RMGT 9 Series.”

"When it came time to buy a new press, we went with the most current and proven technology"

“Our current clientele prints on a lot of synthetic substrates,” states Rudy Desousa, Vice President of Sales, Pioneer Press. “These sheets can take a few days to dry, and they take up a lot of room while drying. With the RMGT, the vinyl sheets are dry immediately off press. We can trim them and get them out the door, giving our customers faster turn times.”

“When you live in a state as beautiful as Colorado, how our processes impact the environment is always a consideration.” continues SoRelle. “We recycle a large percentage of our waste, but when we learned how LED-UV reduces our carbon footprint by using 81% less energy, that certainly got our attention. It makes sense, we all know how efficient LED light bulbs are compared to incandescent, and how long they last!” agrees Desousa. RMGT uses an LED UV system that is instant on/instant off, unlike traditional ARC curing lamps that stay on all day. It also cures at a very low temperature using minimal energy, and the ink it uses are 0% VOC (volatile organic compounds). The active color management system allows Pioneer to use far less paper to get the press, up to color” and the size chosen uses roughly 30% less raw material for plates and paper than the larger presses. “All of these things are good for our environment and our customers!” concludes SoRelle.

"How our processes impact the environment is always a consideration"

“Pioneer Press has flourished during the global slowdown due to their philosophy of “Putting Personality Back in Printing,” states Kian Hemmen, Director of Sales, Print & Finishing Solutions, Western US Distributor for RMGT. “From our initial meeting with Cris and his team you can tell that this resonates within their company, in their client relationships, as well as working with them as a vendor. People buy from people. It was obvious from the onset that Pioneer Press has a way of building deep relationships that are ongoing, in addition to being a high-quality printer. There is no limit to how far their success can go. We are thrilled to partner with them in their strategic planning and celebrate their commitment to print.”

“The horticultural tag and label market exploded for us during the COVID pandemic,” states Josh Hoffmann, President, Primary Color LLC. “All through 2020 and 2021, everyone was at home working on their yards. Our horticultural customers were shipping more plants into their distribution channels, increasing the demand for more tags. Another industry that we saw growing rapidly was packaging, and we continue to do a steady increase of folded cartons.”

“We print the plant tags on a polypropylene substrate,” continues Hoffmann. “Years before the supply chain issues began that has affect printers access to paper and other substrates, we began sourcing directly from Europe. Throughout 2020 and 2021 we had zero supply issues. By ordering consignments of material to meet our needs throughout the year, the recent disruption the marketplace is experiencing has not impact our production.”

Five-Color RMGT 940 offset press, with UV curing and camera system change the game

In addition to increasing the print capacity at Primary Color, their investment in offset printing has taken significant cost out of their business. “We have reduced our makeready by 66%,” states Hoffmann. “Before we upgraded to the RMGT 940, it required 400 to 500 sheets to get up to color and registration. Now we are doing that in about a 100 to 150 sheets. When you are purchasing sheets of material at $1 a sheet and you start reducing that cost by two-thirds, that’s a lot of dollars that go to the bottom line.”

Moving digital jobs to offset for maximum cost efficiency

“Primary Color is another example of printers who are flourishing during the global slowdown,” states Kian Hemmen, Director of Sales, Print & Finishing Solutions, Western US Distributor for RMGT. “One element of their success can be attributed to the foresight of upgrading aging sheetfed offset press operations. We are thrilled to partner with them and celebrate their commitment to print.”

CARNEYS POINT, NJ – Feb 2, 2022 – RMGT, manufacturer of the leading 8-up sheetfed offset press in North America, announces that Envision3 is the most recent printing operation in North America to install the new 8-UP+ RMGT 970 offset press. Based in the greater Chicago area in Bloomingdale, IL, Envision3 is one of the top 300 largest printing and mailing manufacturers in the country and is a full-service offset and digital printing, packaging, mailing, and finishing company. Since its inception in 2000, Envision3 has been a traditional 40” shop having installed three Mitsubishi presses in this time period. Since Mitsubishi merged with Ryobi to form RMGT, Envision3 recently expanded their offset press line with the newly introduced RMGT 970 press.

“We've been a Mitsubishi shop, now RMGT, for the 21 years since our formation,” states Kevin Franz, President, Envision3. “Mitsubishi and RM Machinery have won our business multiple times through the years with their new presses and great service.” Envision3 started in 2000 with a 40-inch and a 28-inch Mitsubishi offset press and later moved on to the Mitsubishi Diamond 3000 series. In the last quarter of 2021, Envision3 installed the latest addition to the 9 Series family, the RMGT 970, which features a new 25” x 38” sheet size.

The RMGT 970 8-UP+ featuring a 25” x 38” sheet size

“One of the features of the RMGT 970 is ability to print up the 24-point board stock,” states Lloyd Molloy, Director of Customer Service, RM Machinery. “Running at speeds of up to 16,000 sheets per hour, the RMGT 970, with a 25” x 38” sheet size is a true 8-up press that can be run with just one press operator,” observes Molloy. “Their press has fully-automatic plate changers, and LED-UV curing capabilities in the units and in the delivery. The new RMGT 970 press also can include ASAP, Automated Smart Assist Printing.”

Changing the game with Automated Smart Assist Printing

Categories

All

Events

LED UV

LED-UV

Newsletters

Packaging

Press Releases

SMART RPC

Testimonials

Archives

June 2024

April 2024

January 2024

December 2023

November 2023

September 2023

May 2023

April 2023

February 2023

December 2022

October 2022

September 2022

July 2022

May 2022

March 2022

January 2022

October 2021

August 2021

June 2021

May 2021

April 2021

February 2021

January 2021

December 2020

November 2020

September 2020

August 2020

July 2020

June 2020

May 2020

April 2020

March 2020

February 2020

November 2019

October 2019

September 2019

August 2019

July 2019

May 2019

April 2019

February 2019

January 2019

December 2018

November 2018

September 2018

July 2018

June 2018

April 2018

March 2018

February 2018

January 2018

December 2017

November 2017

October 2017

September 2017

August 2017

July 2017

June 2017

May 2017

April 2017

March 2017

January 2017

November 2016

October 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

March 2016

February 2016

January 2016

November 2015

October 2015

September 2015

August 2015

July 2015

June 2015

April 2015

March 2015

February 2015

January 2015

October 2014

September 2014

August 2014

November 2013